Team 15 Kennametal - Operational Improvement of Round Tool Manufacturing

Project Abstract

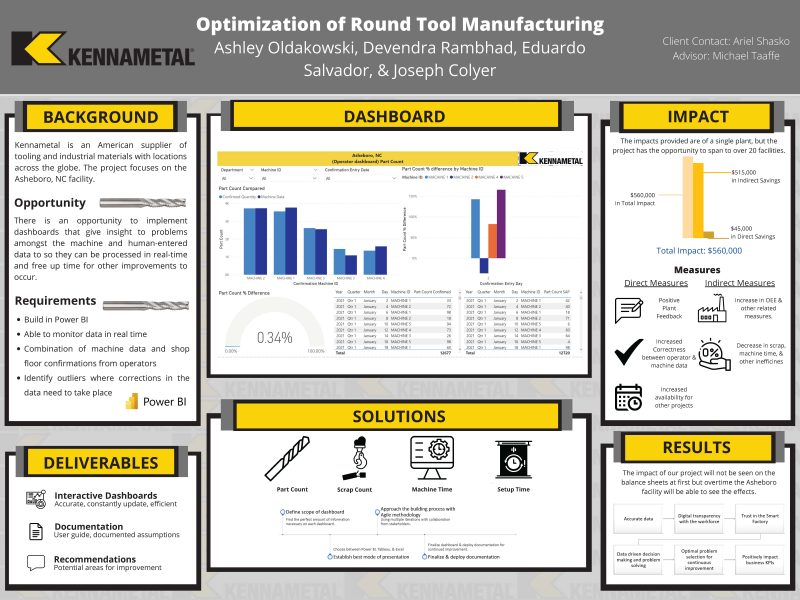

Kennametal is one of the largest manufacturers of cutting tools in the world. Their facility in Asheboro, North Carolina is in the process of a digital transformation to become a Smart Factory, which includes gathering machine data via a new online functionality. To effectively validate the data returned by Kennametal’s Smart Factory, the team was tasked with creating dashboards that displayed side-by-side comparisons of operator data to machine feedback data. The dashboards will have an immediate impact on the Asheboro plant, they will allow for real-time discrepancies to be visible to the operators and managers so they can perform root-cause analysis. This will gradually improve the reliability of the Smart Factory system. The potential impact at a single facility is expected to be $560,000 over the next three years, with a maximum potential of $11.2 Million if implemented in all similar Kennametal facilities.

Members: Eduardo Alberto Salvador Cardoze, Joey Colyer, Ashley Rose Oldakowski, Devendra Rambhad

Faculity Advisor: Dr. Michael Taaffe

Company Contact: Ariel Shasko

CONTACT US

ISE Senior Design Program

Hours: 8a.m. - 5p.m.

Ph: 540.231.1810

Matt Earnest, Director

Center for High Performance Manufacturing

mearnest@vt.edu

MENU

• Student Experience

• Become a Partner

• Expertise

• Make an Impact

• Feature Projects

• Partners