Team 3 - Trail King

Project Abstract

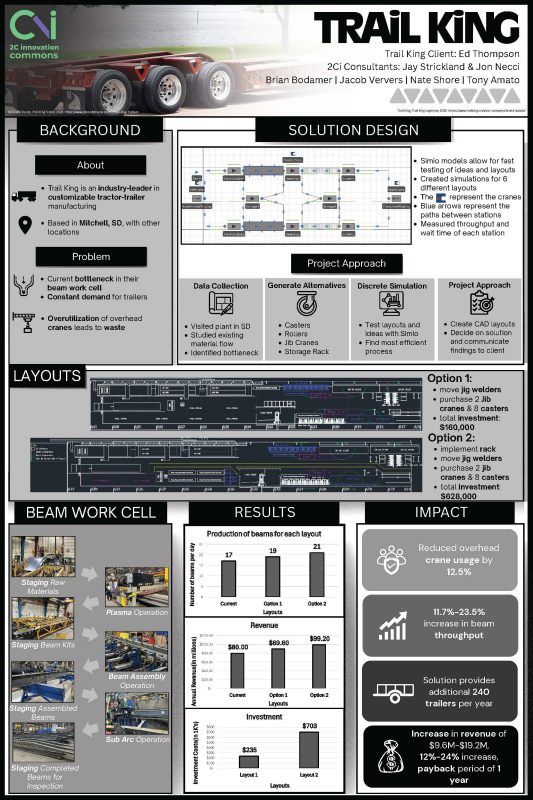

Trail King, located in Mitchell, SD, specializes in manufacturing custom trailers. Our project focuses on improving the manufacturing process of the beam work cell which is currently a bottleneck in their facility. In the current state of this process, they are only producing 16 I-Beams a day which can’t keep up with their current demand for trailers. Trail King produces a wide range of customized I-Beams, and we were tasked with identifying inefficiencies and optimizing their manufacturing processes while maintaining safety principles.

In September, we visited the Trail King facility to build a map of the beam material flow and identify impacts on the throughput of the beam cell. Using a heuristic evaluation method, we assigned a value to each impact, to determine the best area to focus our efforts on. From there, we developed alternate layouts based on our material flow map redesigns and translated each of these into Simio simulations, to evaluate and recommend the most efficient cell layout.

Through our analysis and simulation, we were able to identify an optimized layout to improve the use of overhead cranes and reduce the idle time of each station. By decreasing unneeded material handling and reducing the downtime for equipment, our simulations increased the daily production of I-Beams up to 31.25%. This improvement helps with increasing the overall trailer production, creating a better bond and client satisfaction, and allowing Trail King to be more competitive in the field of trailer manufacturing.

Team Members

Brian Bodamer; Tony Amato; Nathan Shore; Jacob Ververs

Client Contact

Jay Strickland; Jon Necci; Ed Thompson

Advisor

Dr. Andrea L’Afflitto